Thermal Printer Maintenance Tips

Thermal printers are just like cars that require maintenance and upkeep. Many times a label printer is deployed into a warehouse or production environment and never given any attention until it starts having poor print quality or breaks down! Here are some tips to keep your printer operating smoothly and increase the life of its consumable parts.

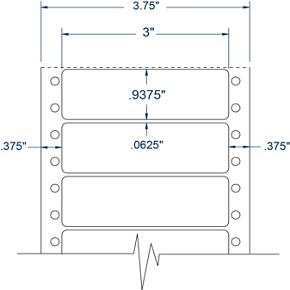

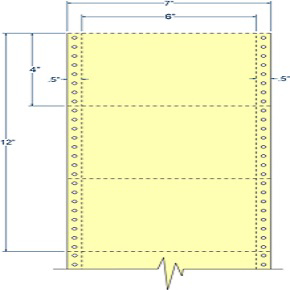

First let's talk about media selection and feeding. A common culprit of label jams is the label alignment being off slightly during feeding causing the label to pass through the print head at an angle. This issue is more prevalent with fanfold labels. Make sure your labels are fed through your machine properly and all label guides are positioned correctly. Here are a few more suggestions for fanfold feeding. First, make sure the label stack is aligned behind the printer through your printer's label feeding slot. When working in a tight environment, it may be beneficial to switch to rolls housed inside the printer. Often a stack of labels accidently gets bumped or caught up in power cords causing jams inside the printer. Using rolls instead of fanfold can reduce jamming due to the entire feeding process being internal to the printer. You can also use a label holder for rolls or fanfold behind the printer to keep alignment in check and the stack standing upright. Some operators have success feeding fanfold labels directly from the carton they ship in, but your will want remove and obstructions like plastic wrap or cardboard flaps that may interfere with feeding.

Cleaning

I often see the cover open on industrial thermal label printers. It is important to keep the covers closed, especially in a warehouse environment to keep dust out of the printer! Fanfold labels will still feed with the cover closed through the feeding slot, and you may get better alignment this way.

Lots of label dust will accumulate in the printer over time. I recommend using canned air to blow out the printer with all media is removed

Every time you insert new labels into the printer, think about cleaning the thermal print head. Over time adhesive and label particles will build up on the print head and reduce image print quality. Ignoring your print head will lead to replacing your expensive printhead much sooner than necessary. Clean the print head before printing with a thermal label cleaning pen. The solution in the pen will eat away any adhesive and remove debris. There should be no need to wipe with an abrasive cloth that may damage the printhead. There are also thermal printer cleaning cards that can be used. Let the printhead dry completely before using.

Consumable Parts

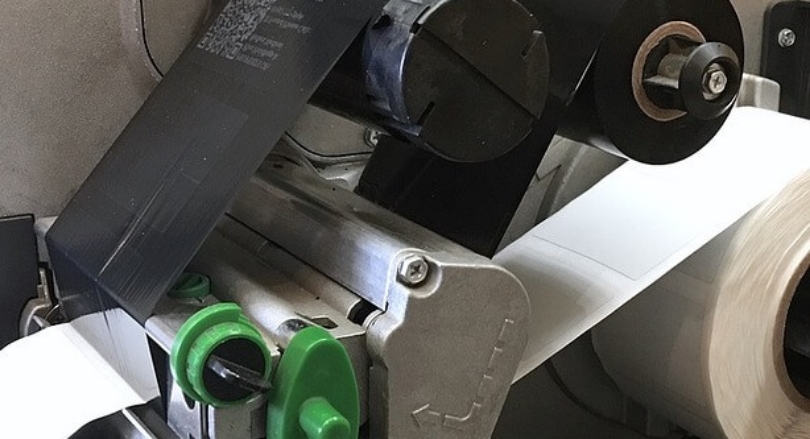

A few parts in the printer are meant to be replaced over time. Two of these parts are the printhead and the platen roller (depending on your printer make and mode). Printhead life is measured in millions of linear inches. To get anywhere near the expected printhead's life you must clean the printhead regularly! Before jumping to replacing a printhead due to poor print quality, make sure the print head is clean, pressure to the label is applied appropriately, and your darkness or heat settings are set correctly. Use the lowest heat setting that produces an image that works well for you. The lower the heat setting, the longer the life of the printhead. Do not touch the print head with your fingers as this will leave oils which may also affect the printheads print quality.

Most industrial thermal label printers have a platen roller that will need to be replaced over time. Typically, you only replace these as needed. You will see wear on the roller and sometimes ripping. Once the roller wears, you will start experiencing issues with labels feeding or seeing poor print quality due to pressure not being applied evenly. You should also clean the platen roller frequently. Use a lint free cloth dipped in 99% isopropyl alcohol.

With these tips you can increase your printer's operational time, reduce troubleshooting, and increase your printer's overall life!